Home made Reactive Target

Posted: Sat Apr 27, 2013 6:00 pm

Hi

I was having a discussion with Harsh regarding making of a cheap reactive target that could be shot again and again without any need of replacing/repositioning. The target should have multiple size point and should be reactive so as to give indication of a hit. It should be portable & easy to carry anywhere without any hassle.

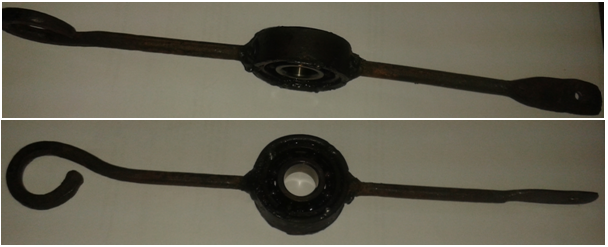

For this I collected 3 damaged bearings of ceiling fan from electrical repair shop (got it for free), then a stem of a tree, 4mm thick iron rod. Then I cut 6 pieces (5 pieces @ 10cm & 1 piece @ 15cm) from that rod and took it to a blacksmith for flattening the top section (1”) and making holes in spike. Then the 15cm spike was turned it into a shape of a hook. I also asked the blacksmith to make me 6 numbers round pieces from a metal sheet of dia 1” & 1.5” (16 gauge steel sheet blacksmith’s term) and punched hole in that too that are equal to the holes made in the spikes.

After that I went to a welding shop for welding the spikes to bearings. I thought of making two targets with 4 spikes of equal size on one bearing at an angle of 90o to each other. And in the second bearing with 2 spikes at an angle of 180o to each other. At one end there was a spike and on other end there was a hook which would act as counter weight. The flattened portion of the spikes should always be in the direction of the rotation of the bearing.

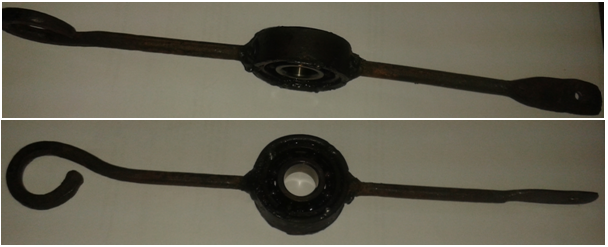

There I started facing problem, when I got the spikes arc welded directly to the bearing, the balls in the bearing got jammed due to overheating. I was not sure of gas welding as the spikes would not adhere to the bearings and the pellet hit may dismantle the spike. Then I thought of welding the spikes on a rounded metal strip (length slightly small to the circumference of the bearing) and then sliding the bearing in to the housing. Then the housing was given little of arc touch so as to grip the bearing. After that my idea went off the window as the bearing was not playing as smoothly as was before. May be the final touch did damage the balls again.

That night tried to make bearing rotate smoothly by chipping off the extra welded material that might adhere to the bearing. Next day, frustrated I put those bearings on the spindle(loose fit), made out of that stem of the tree and tied wire so as let the bearing freely move on the spindle but not slide out of it. Then the rounded metal sheets were attached to the end of spikes using nut & bolt. The rounded metal sheets can be fixed by using arc welding but then it will be permanently fixed & the size of the target will not be changeable. The spindle was then fixed on the stand made out of old furniture legs. I thought of using U clamps for fixing the spindle to the stand but I just used metal wire for tying. Then I fired a test shot & to my delight the bearing made 3 revolutions on the pellet hit with a nice metallic sound. It seemed all the hard work finally paid off.

I coloured the spikes, bearing, the rounded sheets were coloured with different colours so as to give better view on hit of a pellet. In final assembly I greased the spindle & inside of the bearing for smooth play alongwith the metal wire used for restricting the bearing from lateral movement. The total cost for that target is Rs 260(Rs 150 to Blacksmith, Rs 100 to Welder & Rs 10 for nuts & bolts.)

Thanks Moulindu

I was having a discussion with Harsh regarding making of a cheap reactive target that could be shot again and again without any need of replacing/repositioning. The target should have multiple size point and should be reactive so as to give indication of a hit. It should be portable & easy to carry anywhere without any hassle.

For this I collected 3 damaged bearings of ceiling fan from electrical repair shop (got it for free), then a stem of a tree, 4mm thick iron rod. Then I cut 6 pieces (5 pieces @ 10cm & 1 piece @ 15cm) from that rod and took it to a blacksmith for flattening the top section (1”) and making holes in spike. Then the 15cm spike was turned it into a shape of a hook. I also asked the blacksmith to make me 6 numbers round pieces from a metal sheet of dia 1” & 1.5” (16 gauge steel sheet blacksmith’s term) and punched hole in that too that are equal to the holes made in the spikes.

After that I went to a welding shop for welding the spikes to bearings. I thought of making two targets with 4 spikes of equal size on one bearing at an angle of 90o to each other. And in the second bearing with 2 spikes at an angle of 180o to each other. At one end there was a spike and on other end there was a hook which would act as counter weight. The flattened portion of the spikes should always be in the direction of the rotation of the bearing.

There I started facing problem, when I got the spikes arc welded directly to the bearing, the balls in the bearing got jammed due to overheating. I was not sure of gas welding as the spikes would not adhere to the bearings and the pellet hit may dismantle the spike. Then I thought of welding the spikes on a rounded metal strip (length slightly small to the circumference of the bearing) and then sliding the bearing in to the housing. Then the housing was given little of arc touch so as to grip the bearing. After that my idea went off the window as the bearing was not playing as smoothly as was before. May be the final touch did damage the balls again.

That night tried to make bearing rotate smoothly by chipping off the extra welded material that might adhere to the bearing. Next day, frustrated I put those bearings on the spindle(loose fit), made out of that stem of the tree and tied wire so as let the bearing freely move on the spindle but not slide out of it. Then the rounded metal sheets were attached to the end of spikes using nut & bolt. The rounded metal sheets can be fixed by using arc welding but then it will be permanently fixed & the size of the target will not be changeable. The spindle was then fixed on the stand made out of old furniture legs. I thought of using U clamps for fixing the spindle to the stand but I just used metal wire for tying. Then I fired a test shot & to my delight the bearing made 3 revolutions on the pellet hit with a nice metallic sound. It seemed all the hard work finally paid off.

I coloured the spikes, bearing, the rounded sheets were coloured with different colours so as to give better view on hit of a pellet. In final assembly I greased the spindle & inside of the bearing for smooth play alongwith the metal wire used for restricting the bearing from lateral movement. The total cost for that target is Rs 260(Rs 150 to Blacksmith, Rs 100 to Welder & Rs 10 for nuts & bolts.)

Thanks Moulindu