Maha Makeover of IHP35 0.22cal

Posted: Tue Mar 15, 2011 4:24 pm

Hi Guys!

My 5 year old IHP35 in 0.22 cal has been serving me good – however the bug to tune it to enhance its performance & accuracy bit me hard – here’s what I did.

1.Had the stock checkered by laser engraving.

2.The power-plant tube was de-greased with a mixture of 50/50 denatured spirit + ether & polished & applied a light coat of Moly grease.

3.Cleaned the piston assembly & rod & smoothened the sear engagement part.

4.Mounted an original Diana synthetic blue-seal with a custom turned adaptor made of good quality MS.

5.Put a TW Chambers original Diana35 export quality main spring.

6.Inserted a rear end spring guide machined out of SS – 2cms longer than IHP’s original.

7.Fixed a top hat machined out of SS – the whole assembly was coated with Moly Grease.

8.The break-barrel pressure now is 35lbs approx. - measured with a spring balance while cocking.

9.Fitted a custom made scope mounting rail (11mm) machined out of aircraft aluminum & black anodized.

10.Mounted a Walther 4 x 32 ASR scope with duplex reticules & built-in scope stop.

11.Now the “Piece de Resistance” – removed the front sight & fixed a custom designed Muzzle Break CNC machined out of aircraft aluminum with 4 sets of air vents angled at 45*(approx.) & black anodized.

12.The original IHP front sight was then fixed on to the specially cut grooves on the muzzle break – thus giving me the option to use either open sights or the scope.

13.The weapon now has an international look & when shouldered feels good – when I shoot the report is a macho THWAK!!! However the sound varies with different makes of pellets, depending on its construction (round head / wad cutter / hollow point / pointed / steel tipped) & fitment in the breech. Master Shot & Marshall Shot fit nicely, while the G Smith & International Export quality pellets fit snugly – I personally like this fit.

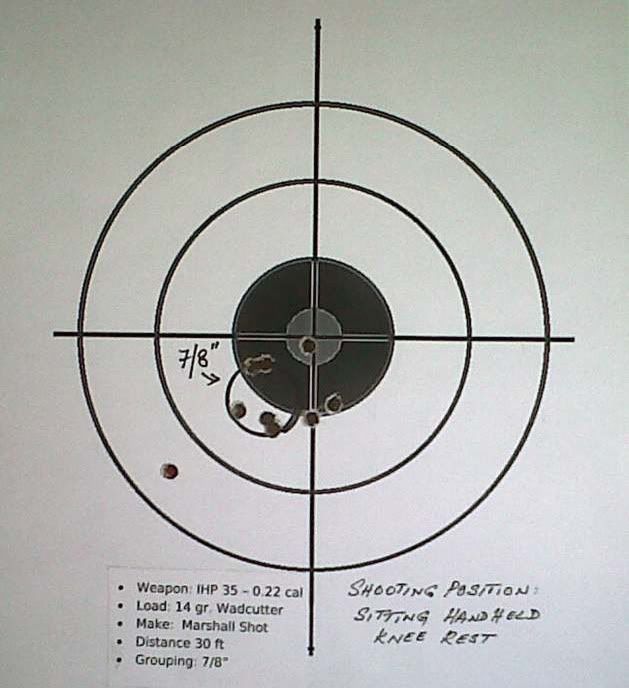

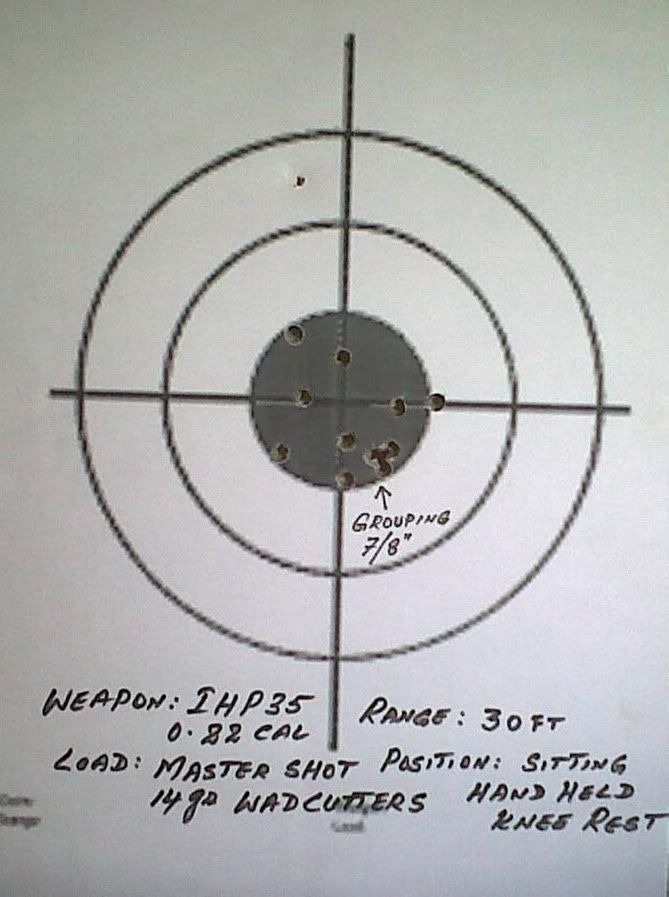

•The G Smith & International Export quality pellets give me better groups (5/8’’ & 7/8”) at 25ft - in sitting position / knee rested with artillery hold. Using a bi-pod or bench rest could perhaps give better results!

•Round heads & Pointed pellets went through & exited in metal aerosol cans – managed to put 3 shots in the same hole!

•Both round heads & pointed pellets whistled through ¼” – 6mm Marine ply – Got 5/8” group using International Export quality Pointed pellets.

•Fps measured with hand-held laser-chronograph using 14gr Roundhead pellets were - 650, 640, 625, 620, 675, 650, 670, 630, 650 & 650. Hence FPE would be around 17 to 18 approx. at the muzzle and about 7 to 8 FPE @ 25 yards if 16gr pellets are used – good enough for taking small game with a well place shot.

•A word of advice from me gained through experience, and as concurred by Air Rifle Gurus is that, each air rifle performs differently with different types of pellets, springs, seals, rear guides & top hats.

•Hence select the pellet that performs consistently accurate in your weapon giving groups of 5/8” or 7/8” at 25ft and stick to it.

•This can be achieved only by firing at least 50 to 100 pellets each of different shapes.

•In my case G. Smith & International Export perform exceedingly well. Smooth firing, no vibration & consistent accuracy.

•The only part I couldn’t play around with was the trigger – wish I could make it a shade smoother. My cry for help led me towards a blank wall – ‘WHAT THE HELL’ – I’ve learned to adjust to it as is and have come out none the worse!!!

•Attached are a few pictures, provided with details – hope you’ll like them!

Cheers - Brihacharan

My 5 year old IHP35 in 0.22 cal has been serving me good – however the bug to tune it to enhance its performance & accuracy bit me hard – here’s what I did.

1.Had the stock checkered by laser engraving.

2.The power-plant tube was de-greased with a mixture of 50/50 denatured spirit + ether & polished & applied a light coat of Moly grease.

3.Cleaned the piston assembly & rod & smoothened the sear engagement part.

4.Mounted an original Diana synthetic blue-seal with a custom turned adaptor made of good quality MS.

5.Put a TW Chambers original Diana35 export quality main spring.

6.Inserted a rear end spring guide machined out of SS – 2cms longer than IHP’s original.

7.Fixed a top hat machined out of SS – the whole assembly was coated with Moly Grease.

8.The break-barrel pressure now is 35lbs approx. - measured with a spring balance while cocking.

9.Fitted a custom made scope mounting rail (11mm) machined out of aircraft aluminum & black anodized.

10.Mounted a Walther 4 x 32 ASR scope with duplex reticules & built-in scope stop.

11.Now the “Piece de Resistance” – removed the front sight & fixed a custom designed Muzzle Break CNC machined out of aircraft aluminum with 4 sets of air vents angled at 45*(approx.) & black anodized.

12.The original IHP front sight was then fixed on to the specially cut grooves on the muzzle break – thus giving me the option to use either open sights or the scope.

13.The weapon now has an international look & when shouldered feels good – when I shoot the report is a macho THWAK!!! However the sound varies with different makes of pellets, depending on its construction (round head / wad cutter / hollow point / pointed / steel tipped) & fitment in the breech. Master Shot & Marshall Shot fit nicely, while the G Smith & International Export quality pellets fit snugly – I personally like this fit.

•The G Smith & International Export quality pellets give me better groups (5/8’’ & 7/8”) at 25ft - in sitting position / knee rested with artillery hold. Using a bi-pod or bench rest could perhaps give better results!

•Round heads & Pointed pellets went through & exited in metal aerosol cans – managed to put 3 shots in the same hole!

•Both round heads & pointed pellets whistled through ¼” – 6mm Marine ply – Got 5/8” group using International Export quality Pointed pellets.

•Fps measured with hand-held laser-chronograph using 14gr Roundhead pellets were - 650, 640, 625, 620, 675, 650, 670, 630, 650 & 650. Hence FPE would be around 17 to 18 approx. at the muzzle and about 7 to 8 FPE @ 25 yards if 16gr pellets are used – good enough for taking small game with a well place shot.

•A word of advice from me gained through experience, and as concurred by Air Rifle Gurus is that, each air rifle performs differently with different types of pellets, springs, seals, rear guides & top hats.

•Hence select the pellet that performs consistently accurate in your weapon giving groups of 5/8” or 7/8” at 25ft and stick to it.

•This can be achieved only by firing at least 50 to 100 pellets each of different shapes.

•In my case G. Smith & International Export perform exceedingly well. Smooth firing, no vibration & consistent accuracy.

•The only part I couldn’t play around with was the trigger – wish I could make it a shade smoother. My cry for help led me towards a blank wall – ‘WHAT THE HELL’ – I’ve learned to adjust to it as is and have come out none the worse!!!

•Attached are a few pictures, provided with details – hope you’ll like them!

Cheers - Brihacharan