Ka Bar USMC Knife history, Field Trial & Review (Pic Heavy)

Posted: Sat Mar 23, 2013 6:23 am

Ka Bar USMC 1217

A little bit of History...

The owner of the KA-BAR trademark, the Union Cutlery Co. of Olean, New York, began using the name on its knives and in its advertising in 1923 after receiving a testimonial letter by a fur trapper, who used the knife to kill a wounded bear that attacked him after his rifle jammed. According to company records, the letter was only partially legible, with "ka bar" readable as fragments of the phrase "kill a bear". In 1923, the company adopted the name KA-BAR from the "bear story" as their trademark.

After the US entry into World War II, complaints arose from Army soldiers and Marines issued World War I-era bronze or alloy-handled trench knives such as the U.S. Mark I trench knife for use in hand-to-hand fighting. The Mark I was relatively expensive and time-consuming to manufacture, and reports from the field indicated that the knife's large 'brass-knuckle' fingerguard handle made it difficult to secure in conventional scabbards while limiting the range of useful fighting grip positions.

Mark I Trench Knife used by US forces

Another criticism was that the Mark I's relatively thin blade was prone to breakage when used for common utility tasks such as cutting wire, opening ammunition crates and ration tins. A final impetus came from the War Department, which had determined the need for a new multipurpose knife capable of fulfilling the roles of both a fighting and a utility knife, while at the same time conserving strategic metal resources.

Working with the Camillus Cutlery Co., USMC Colonel John M. Davis and Major Howard E. America contributed several important changes, including a longer, stronger blade, the introduction of a small fuller to lighten the blade, a peened pommel (later replaced by a pinned pommel), a straight (later, slightly curved) steel crossguard, and a stacked leather handle for better grip. The blade, guard, and pommel were coated with a non-reflective matte phosphate finish instead of the brightly polished steel of the original prototype. The design was given the designation of 1219C2. Notably, the 1219C2 used a thicker blade stock than that of the USN Mark 1 utility knife, and featured a stout clip point. After extensive trials, the 1219C2 prototype was recommended for adoption. The Marine Corps adopted the new knife on November 23, 1942, still under the designation 1219C2.

Marine with Ka-Bar on his pistol belt.

Quarter master inspecting Ka Bar knives during World War II

KA-BAR makes Army and Navy versions as well as USMC versions. They are the same as the Marine version except for different initials at the bottom of the blade and different symbols on the sheath. Marines today often give the blades, guards and pommels of their knives a few coats of non-reflective matte black spray paint to reduce reflected light and give them a little more protection against saltwater corrosion. Its moderate carbon and low chromium steel mixture allows the blade to hold an edge very well. The 1095 chrome-vanadium steel[citation needed] used in the blades of contemporary KA-BARs has a hardness of 56–58 HRC, while the guard and pommel are made from sintered 1095 carbon steel. Besides use as a fighting knife, the It has proven its usefulness as a utility knife, used for opening cans, digging trenches, and cutting wood, roots, wire, and cable.

KA-BAR’s wartime production totaled more than 1 million. The KA-BAR knives became so well recognized for their quality and so abundant in number that “Kabar” became the name by which many referred to this knife pattern, regardless of whether the knife was manufactured at the KA-BAR facility.

Specs:

#1217 Full-size USMC KA-BAR, Straight Edge

Sheath: Leather

Weight: 0.70 lbs.

Length: Blade 7″

Overall 11 7/8″

Grind: Flat

Shape: Clip

Handle Material: Leather

Stamp: USMC

Edge Angle: 20 Degrees

Steel: 1095 Cro-Van

Country Mft’d: Knife Made in USA, Leather Sheath Made in Mexico

Personal experience:

I bought the knife from Ebay.com after paying 67.95 + 18.95 I.e. 86.9$ (Rs 4710) using my debit card. I chose USPS Intl shipping as it was pretty cheap at 18.95$ , though the shipment was not insured. I was instantly provided a tracking no. By the seller. Initially I was a bit sceptical about the basic postal service as most of the guys had advised me to select USPS priority mail instead...Anyway, I was pleasantly surprised when it arrived in one week time

First impression:

The knife came packed in an el cheapo plastic pack.

Sheath:

Leather sheath which is made in Mexico is brown in Color with Ka Bar, USMC and logo stamped on the front. There's also a drainage hole in the lower portion of sheath which can also be used for lanyard placement if one desires. There's provision for vertical carry by attaching the sheath to belt. But the problem is that you cannot remove/attach the sheath without de buckling your belt. The knife fits snugly into the sheath. Overall the sheath appeared pretty average to me. You can already see signs of wear & tear after couple of hours of use. I don't think it would be able to hold up against moisture, dirt and rain for long. I am already thinking of getting a new Kydex/hardened plastic sheath for my knife.

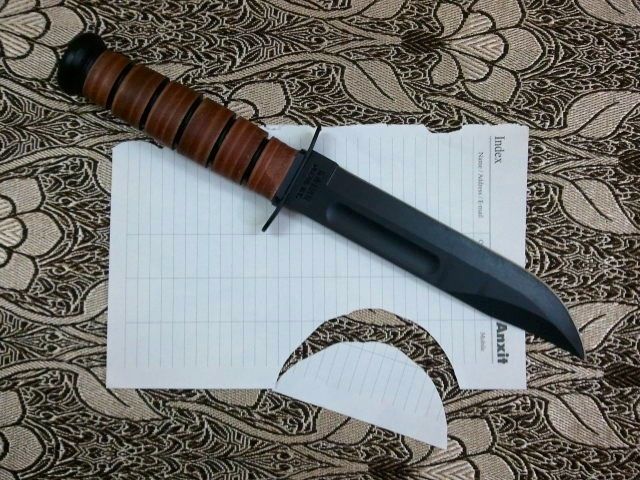

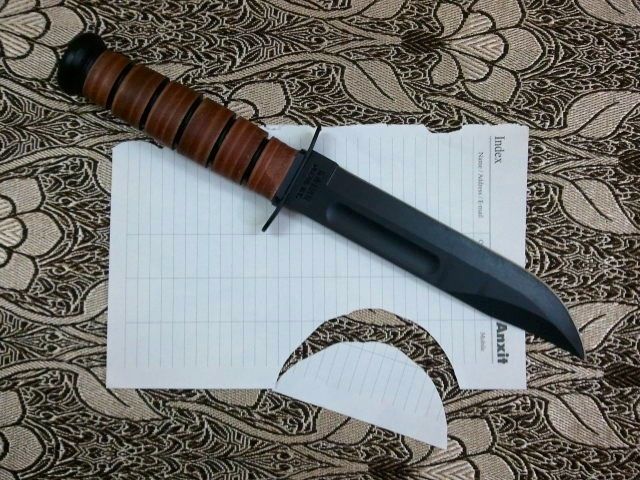

Knife:

Knife is undoubtedly a piece of art. Looks pretty mean but also elegant at the same time. If you understand what I am trying to convey. The Handel/grip takes some time to getting used to..but after sometime it feels pretty comfortable. Handles are shaped from 6 oval, stacked leather segments for a comfortable, non-slip grip. Pommels are made from a powdered metal process and hand guards are carbon steel. All of the metal surfaces are finished in powder coat matte black to give corrosion protection and eliminate glare. Pommel is pretty sturdy and it seems that it can be used for trivial hammering job in cases of emergency. The clip point blade is 7" in length & is Teflon coated. The factory edge is sharp but I guess it can be further sharpened.

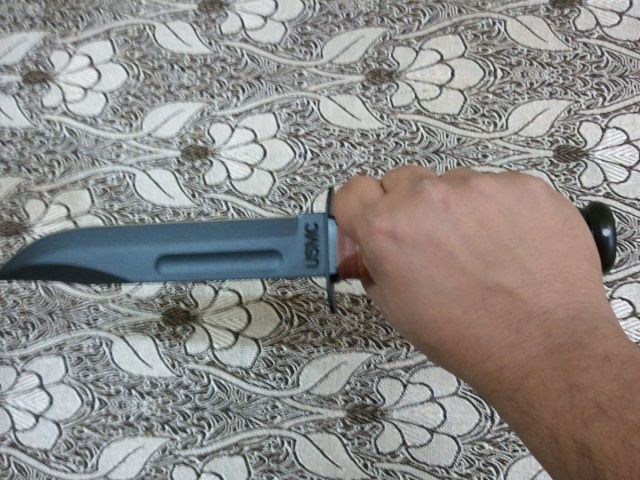

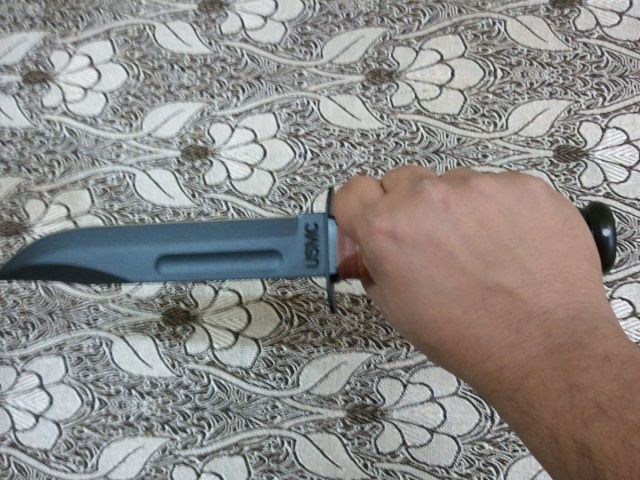

Grip feels pretty comfy..

Took the knife in the woods and subjected it to a bit of chopping, scrapping, bush clearing etc. it came out with flying colors. At one point of time I hinged it into the dry soil and used it to climb up a ridge. I guess it has got all the quality for making it into a decent camping knife.

Factory edge is pretty sharp..It was slicing and chopping the wood like butter..

Medium sized weeds & bushes en route wasn't posing any problem for Ka Bar..

During all the chopping, scrapping and photo-shoot we managed to scare away couple of Neel Gais and one spotted deer. Will try to shoot them with my camera some other day..

Tried cutting a semicircular piece of paper after the day's torture in woods..

As of now it's holding the edge pretty well...

-Nishith

A little bit of History...

The owner of the KA-BAR trademark, the Union Cutlery Co. of Olean, New York, began using the name on its knives and in its advertising in 1923 after receiving a testimonial letter by a fur trapper, who used the knife to kill a wounded bear that attacked him after his rifle jammed. According to company records, the letter was only partially legible, with "ka bar" readable as fragments of the phrase "kill a bear". In 1923, the company adopted the name KA-BAR from the "bear story" as their trademark.

After the US entry into World War II, complaints arose from Army soldiers and Marines issued World War I-era bronze or alloy-handled trench knives such as the U.S. Mark I trench knife for use in hand-to-hand fighting. The Mark I was relatively expensive and time-consuming to manufacture, and reports from the field indicated that the knife's large 'brass-knuckle' fingerguard handle made it difficult to secure in conventional scabbards while limiting the range of useful fighting grip positions.

Mark I Trench Knife used by US forces

Another criticism was that the Mark I's relatively thin blade was prone to breakage when used for common utility tasks such as cutting wire, opening ammunition crates and ration tins. A final impetus came from the War Department, which had determined the need for a new multipurpose knife capable of fulfilling the roles of both a fighting and a utility knife, while at the same time conserving strategic metal resources.

Working with the Camillus Cutlery Co., USMC Colonel John M. Davis and Major Howard E. America contributed several important changes, including a longer, stronger blade, the introduction of a small fuller to lighten the blade, a peened pommel (later replaced by a pinned pommel), a straight (later, slightly curved) steel crossguard, and a stacked leather handle for better grip. The blade, guard, and pommel were coated with a non-reflective matte phosphate finish instead of the brightly polished steel of the original prototype. The design was given the designation of 1219C2. Notably, the 1219C2 used a thicker blade stock than that of the USN Mark 1 utility knife, and featured a stout clip point. After extensive trials, the 1219C2 prototype was recommended for adoption. The Marine Corps adopted the new knife on November 23, 1942, still under the designation 1219C2.

Marine with Ka-Bar on his pistol belt.

Quarter master inspecting Ka Bar knives during World War II

KA-BAR makes Army and Navy versions as well as USMC versions. They are the same as the Marine version except for different initials at the bottom of the blade and different symbols on the sheath. Marines today often give the blades, guards and pommels of their knives a few coats of non-reflective matte black spray paint to reduce reflected light and give them a little more protection against saltwater corrosion. Its moderate carbon and low chromium steel mixture allows the blade to hold an edge very well. The 1095 chrome-vanadium steel[citation needed] used in the blades of contemporary KA-BARs has a hardness of 56–58 HRC, while the guard and pommel are made from sintered 1095 carbon steel. Besides use as a fighting knife, the It has proven its usefulness as a utility knife, used for opening cans, digging trenches, and cutting wood, roots, wire, and cable.

KA-BAR’s wartime production totaled more than 1 million. The KA-BAR knives became so well recognized for their quality and so abundant in number that “Kabar” became the name by which many referred to this knife pattern, regardless of whether the knife was manufactured at the KA-BAR facility.

Specs:

#1217 Full-size USMC KA-BAR, Straight Edge

Sheath: Leather

Weight: 0.70 lbs.

Length: Blade 7″

Overall 11 7/8″

Grind: Flat

Shape: Clip

Handle Material: Leather

Stamp: USMC

Edge Angle: 20 Degrees

Steel: 1095 Cro-Van

Country Mft’d: Knife Made in USA, Leather Sheath Made in Mexico

Personal experience:

I bought the knife from Ebay.com after paying 67.95 + 18.95 I.e. 86.9$ (Rs 4710) using my debit card. I chose USPS Intl shipping as it was pretty cheap at 18.95$ , though the shipment was not insured. I was instantly provided a tracking no. By the seller. Initially I was a bit sceptical about the basic postal service as most of the guys had advised me to select USPS priority mail instead...Anyway, I was pleasantly surprised when it arrived in one week time

First impression:

The knife came packed in an el cheapo plastic pack.

Sheath:

Leather sheath which is made in Mexico is brown in Color with Ka Bar, USMC and logo stamped on the front. There's also a drainage hole in the lower portion of sheath which can also be used for lanyard placement if one desires. There's provision for vertical carry by attaching the sheath to belt. But the problem is that you cannot remove/attach the sheath without de buckling your belt. The knife fits snugly into the sheath. Overall the sheath appeared pretty average to me. You can already see signs of wear & tear after couple of hours of use. I don't think it would be able to hold up against moisture, dirt and rain for long. I am already thinking of getting a new Kydex/hardened plastic sheath for my knife.

Knife:

Knife is undoubtedly a piece of art. Looks pretty mean but also elegant at the same time. If you understand what I am trying to convey. The Handel/grip takes some time to getting used to..but after sometime it feels pretty comfortable. Handles are shaped from 6 oval, stacked leather segments for a comfortable, non-slip grip. Pommels are made from a powdered metal process and hand guards are carbon steel. All of the metal surfaces are finished in powder coat matte black to give corrosion protection and eliminate glare. Pommel is pretty sturdy and it seems that it can be used for trivial hammering job in cases of emergency. The clip point blade is 7" in length & is Teflon coated. The factory edge is sharp but I guess it can be further sharpened.

Grip feels pretty comfy..

Took the knife in the woods and subjected it to a bit of chopping, scrapping, bush clearing etc. it came out with flying colors. At one point of time I hinged it into the dry soil and used it to climb up a ridge. I guess it has got all the quality for making it into a decent camping knife.

Factory edge is pretty sharp..It was slicing and chopping the wood like butter..

Medium sized weeds & bushes en route wasn't posing any problem for Ka Bar..

During all the chopping, scrapping and photo-shoot we managed to scare away couple of Neel Gais and one spotted deer. Will try to shoot them with my camera some other day..

Tried cutting a semicircular piece of paper after the day's torture in woods..

As of now it's holding the edge pretty well...

-Nishith