Preparing an aluminium arrow - fixing insert and fletching. (Wooden arrow tutorial added)

Posted: Sat Apr 16, 2011 2:07 pm

As I have to prepare a dozen arrows for IcemanV and as Yaj, Ashok, et al will need to fix inserts and/or fletch their arrow shafts. I thought I'd do a pictorial essay showing how.

What follows is neither the only way nor the best way. It's merely how I do it with what I have at hand. You can improvise using common sense or if you have deep pockets you could get better equipment to do the needful.

How to fix an insert to an aluminium arrow:

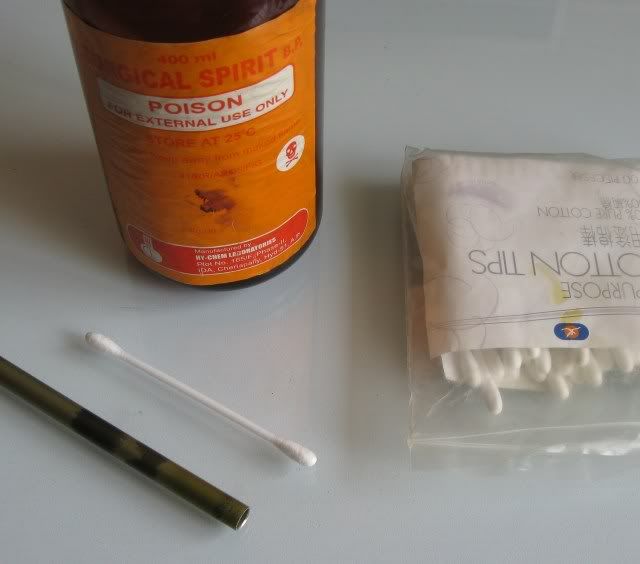

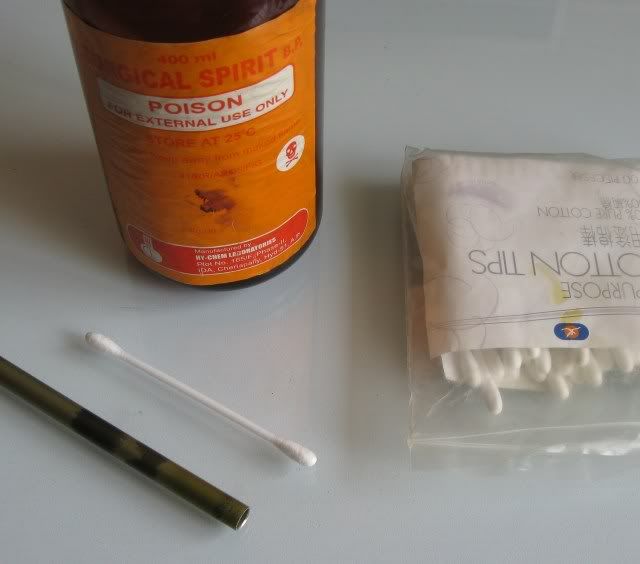

Tools of the trade.

If you need to cut the arrow to a particular length, measure from the valley of the arrow nock towards the tip and mark the point with a pencil. In this particular case, I will be cutting the arrow shaft to 29" BOP (Back Of Point).

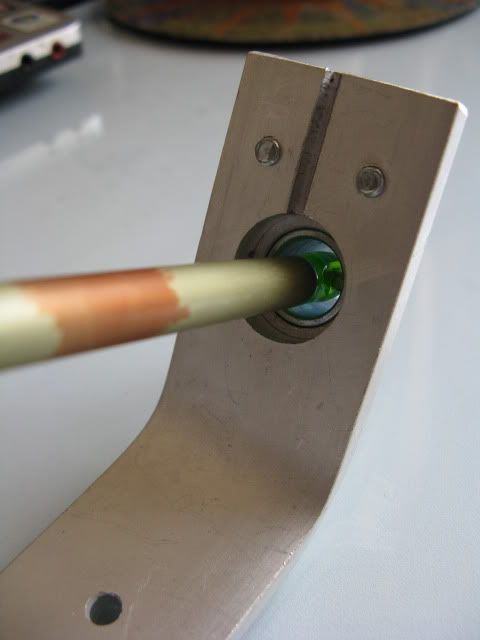

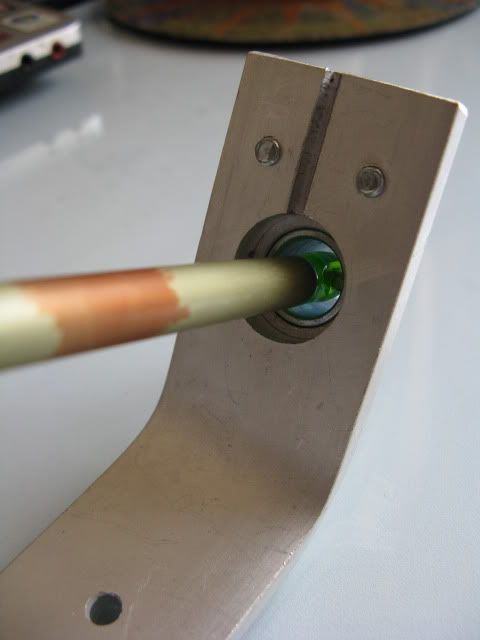

Place the arrow shaft in the tube cutter aligning the pencil mark with the edge of the cutter's circular blade. Do not over-tighten at all! Start rotating the shaft or cutter and gently tighten the cutter after every few revolutions until the shaft is cut.

Hold the shaft vertically with the newly cut end against sand-paper or sharpening stone and rotate the shaft whilst applying uniform downward pressure. This will remove the burrs and smoothen up the cut edge. You must ensure that the shaft is always cut and deburred perpendicular to its longer axis. If you don't, the pile (target point, field point, broadhead, etc.) will sit at an angle and that is not desired.

Use a conical stone or deburring tool to remove any other burrs and cut a slight chamfer into the shaft. The chamfer makes it easier to insert the arrow insert.

Clean and degrease the first couple of inches of the shaft using an ear bud and some surgical spirit or any other degreasing agent.

Screw a pile into the insert.

This is what you will need to apply and fix the insert.

Hold the pile with a plier and heat the insert. You can use a candle, diya, alcohol burner, etc. but please do not over-heat. The soot can be wiped off using a rag.

Heat the stick of hot melt glue and apply the same on the insert.

Push the shaft onto the insert. Push and pull a couple of times and rotate to get an even spread of glue inside the shaft. Then press down on a block of wood, etc.

Let cool for five or ten minutes and then roll off the excess glue that has now solidified into a ring.

Clean the shaft tip and pile and you are done.

To remove the insert, merely heat the pile or shaft end and using a plier pull the insert out.

How to fletch an arrow:

Here, I will be fletching an aluminium arrow with right wing feathers using a right wing fletching jig and fletching tape. This is going to be a three feather fletch using one cock feather (red) and two hen feathers (yellow).

This is what I use.

Ensure that the nock holder on the fletching jig is horizontal. Refer to the manufacturer's instructions on how to do so.

Place the arrow into the fletching jig as per manufacturer's instructions. If the arrow nock has an index marker, this should be aligned with the cock feather.

First, place the cock feather in the clamp, with the rear of the feather aligned with a certain mark on the clamp. Some clamps come pre-marked. Mine did not. This ensures that the feathers aren't stuck to the shaft at random distances from the valley of the nock. I leave 1 1/4" from the rear of the feather to the valley of the nock. Some people leave less distance and others a little more.

Now stick the double sided fletching tape on the quill with a little overhang on either end and cut the tape. Run your finger down the tape on the quill to ensure that it has stuck evenly and there are no air gaps.

Remove the reddish protective strip from the double sided fletching tape. I prefer to use a scalpel or a thin pocket knife.

Place the clamp into the jig, apply a little pressure, remove clamp, run a finger nail down the side of the quill to ensure it's stuck evenly, press and stick the tape overhangs to the shaft and you now have a feather stuck to the shaft with a right helical twist.

Now rotate the shaft on the jig and use the same process to stick the hen feathers.

For added security, you can apply a drop of Fletchtite, etc. or plain old Fevibond on the leading and trailing end of each feather and let dry.

Hope this helps you guys and gals out.

Mack The Knife

What follows is neither the only way nor the best way. It's merely how I do it with what I have at hand. You can improvise using common sense or if you have deep pockets you could get better equipment to do the needful.

How to fix an insert to an aluminium arrow:

Tools of the trade.

If you need to cut the arrow to a particular length, measure from the valley of the arrow nock towards the tip and mark the point with a pencil. In this particular case, I will be cutting the arrow shaft to 29" BOP (Back Of Point).

Place the arrow shaft in the tube cutter aligning the pencil mark with the edge of the cutter's circular blade. Do not over-tighten at all! Start rotating the shaft or cutter and gently tighten the cutter after every few revolutions until the shaft is cut.

Hold the shaft vertically with the newly cut end against sand-paper or sharpening stone and rotate the shaft whilst applying uniform downward pressure. This will remove the burrs and smoothen up the cut edge. You must ensure that the shaft is always cut and deburred perpendicular to its longer axis. If you don't, the pile (target point, field point, broadhead, etc.) will sit at an angle and that is not desired.

Use a conical stone or deburring tool to remove any other burrs and cut a slight chamfer into the shaft. The chamfer makes it easier to insert the arrow insert.

Clean and degrease the first couple of inches of the shaft using an ear bud and some surgical spirit or any other degreasing agent.

Screw a pile into the insert.

This is what you will need to apply and fix the insert.

Hold the pile with a plier and heat the insert. You can use a candle, diya, alcohol burner, etc. but please do not over-heat. The soot can be wiped off using a rag.

Heat the stick of hot melt glue and apply the same on the insert.

Push the shaft onto the insert. Push and pull a couple of times and rotate to get an even spread of glue inside the shaft. Then press down on a block of wood, etc.

Let cool for five or ten minutes and then roll off the excess glue that has now solidified into a ring.

Clean the shaft tip and pile and you are done.

To remove the insert, merely heat the pile or shaft end and using a plier pull the insert out.

How to fletch an arrow:

Here, I will be fletching an aluminium arrow with right wing feathers using a right wing fletching jig and fletching tape. This is going to be a three feather fletch using one cock feather (red) and two hen feathers (yellow).

This is what I use.

Ensure that the nock holder on the fletching jig is horizontal. Refer to the manufacturer's instructions on how to do so.

Place the arrow into the fletching jig as per manufacturer's instructions. If the arrow nock has an index marker, this should be aligned with the cock feather.

First, place the cock feather in the clamp, with the rear of the feather aligned with a certain mark on the clamp. Some clamps come pre-marked. Mine did not. This ensures that the feathers aren't stuck to the shaft at random distances from the valley of the nock. I leave 1 1/4" from the rear of the feather to the valley of the nock. Some people leave less distance and others a little more.

Now stick the double sided fletching tape on the quill with a little overhang on either end and cut the tape. Run your finger down the tape on the quill to ensure that it has stuck evenly and there are no air gaps.

Remove the reddish protective strip from the double sided fletching tape. I prefer to use a scalpel or a thin pocket knife.

Place the clamp into the jig, apply a little pressure, remove clamp, run a finger nail down the side of the quill to ensure it's stuck evenly, press and stick the tape overhangs to the shaft and you now have a feather stuck to the shaft with a right helical twist.

Now rotate the shaft on the jig and use the same process to stick the hen feathers.

For added security, you can apply a drop of Fletchtite, etc. or plain old Fevibond on the leading and trailing end of each feather and let dry.

Hope this helps you guys and gals out.

Mack The Knife