Page 1 of 1

Solving a flyer problem...

Posted: Fri Nov 20, 2009 1:30 pm

by MoA

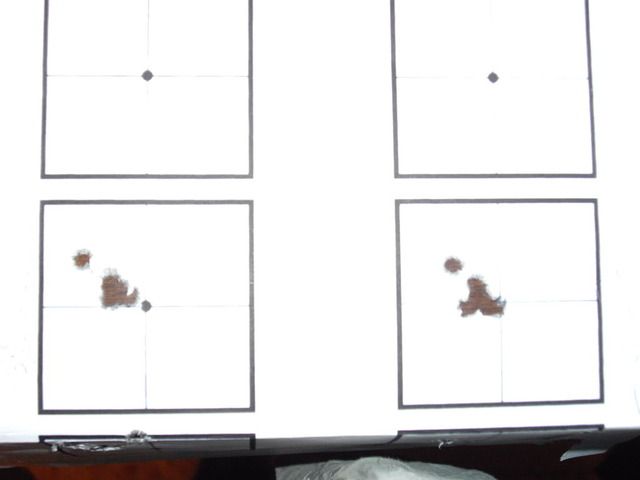

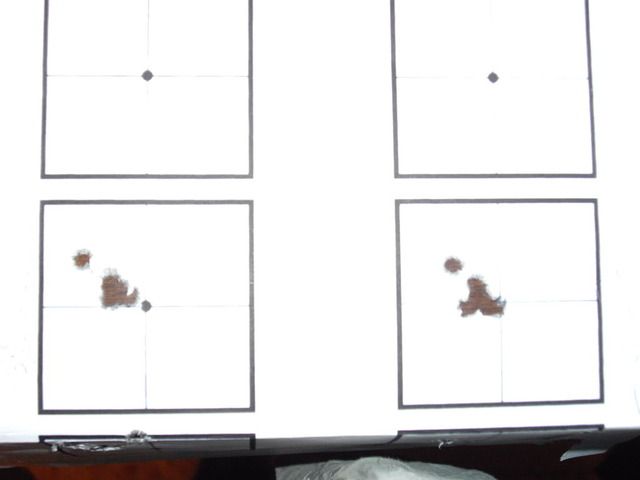

I would keep getting unexplained flyers, consistently and had attributed it to my lack of skill. The loads in the second picture are actually two different powders...

Turns out that my HS Precision stock was actually touching the barrel and preventing a free float in one spot. I just checked it on a whim, and about an inch into the stock, it was touching the barrel. Well have sanded it down so that the barrel is now a true free float, and a dollar bill passes cleanly to the recoil lug.

Testing tomorrow..

Watch the space...

Re: Solving a flyer problem...

Posted: Fri Nov 20, 2009 2:44 pm

by eternalme

some say that pressure bedding is much effective than free float , any comments ??

Re: Solving a flyer problem...

Posted: Fri Nov 20, 2009 3:21 pm

by MoA

I doubt it. If it were, all the precision rifles would be pressure bedded rather than free floated.

Re: Solving a flyer problem...

Posted: Sun Nov 22, 2009 4:59 am

by eternalme

Remington has been following in pressure bedding along with free float concept, in that the complete barrel is FF except at one point.

I buy that as during my experiments with long pipes having projectile travelling inside showed lesser vibration on the far end when the pipe itself was solidly held at one point ahead of origination of projectile.

It was crude experiment but yielded some good results, the longer the pipe the wider the landings, I experimented with shortening the projectile travel , the powder useed, the size of the projectile etc.

The results were like follows -

Short pipe - lesser widening of projectile landing.

No held ahead of projectile origin - wider projectile landing due to wider pipe viberation.

Fuly bedded pipe - resulted in incinsistent projectile landing.

Free float pipe - resulted in wide but known projectile landing.

The pipe was of 11 feet in the beginning and was cut to three feet during subsequent experiments .

Projectile origin and the type can't be menitoned here as its out of context.

Re: Solving a flyer problem...

Posted: Sun Nov 22, 2009 8:01 pm

by MoA

All free floated barrels are floated from the recoil lug on.

Most bench rest barrels are in the 21.75 inch to 30 inch barrel length. Any more and with most contours you get barrel sag.

My rifle will shoot between .1 and .3 MoA with the free float. And do that consistently. It shoots in the high 1's when I do my part, and .3 on an average day. When I shoot badly I still average .4's or .5's. This is with a free floated barrel.

I personally only know of the schutzen type of rifles which have the muzzle bedded. The SMLE/Mauser/Nagant's are all bedded almost to the muzzle but not quite. None of them come close to .3 MoA.

The aim of free floating is to get consistent vibration patterns in the barrel, and that coupled with OBT in theory should provide optimal accuracy. All barrels will vibrate, the longer the barrel, more the vibration. There is a school of thought that the optimal barrel length is 21.75 inches, personally I havent tried one, but who knows some day.

Re: Solving a flyer problem...

Posted: Mon Nov 23, 2009 3:36 am

by eternalme

So what happened to your flyer problem ?

solved or still under observation, sometime if the center of mass of the bullet is not proper then in fast barrels (rifling) they tend to scatter, probably you weigh all your carts and try.

Regards

Re: Solving a flyer problem...

Posted: Mon Nov 23, 2009 1:17 pm

by MoA

Well the flyer prob;lem is solved. Still have some tinkering to do with loads, and I need to get my BP down.

Re: Solving a flyer problem...

Posted: Mon Nov 23, 2009 1:25 pm

by eternalme

how it was solved hope it was not something to do with dis balanced projectile.

Re: Solving a flyer problem...

Posted: Mon Nov 23, 2009 1:51 pm

by MoA

Nope... stock was touching the barrel. Hence an amount of material needed to be removed from it to ensure a clean free float to the recoil lug.