Restoring an American classic : The Remington Rolling Block

Posted: Mon Dec 15, 2014 10:31 pm

Every story has another one behind it. This post won't be complete unless I start with mine.

I was a kid when my dad took me to a movie on that day. Halfway through the movie (I can't recollect the name anymore) a rifle grabbed my attention. A man was loading one bullet at a time and pulling a lever like object that made the empties fly out. It had a long shiny barrel and lovely wooden stock..... I was awestruck.

"That's a Remington rolling block rifle," my father later told me. Soon, this rifle turned into an obsession that I never talked about. But I never again saw a Remington Rolling Block in real life.

Last year, I was visiting an old gun shop in Kolkata when something kept against the wall in a dusty corner caught my eyes and all my attention.

A Remington Rolling Block No 4 later model or the Improved Model 4 with round barrel and distinctively large take down screw. Fires .22 short, long and long rifle. Comes apart in a few seconds and neatly packs into a 24 inch bag. I could hear my heart beat.

OVERVIEW: from here http://www.remington.com/products/archi ... block.aspx

Description: Rolling Block Rifle

Introduction Year: 1890

Year Discontinued: 1933

Total Production: Approximately 356,000

Designer/Inventor: F.A. Houghton, J.O. Simpson, O.H. Loomis

Action Type: Single Shot

Caliber/Gauge: 22 short, 22 long, 22 long rifle, 25 Stevens ("25-10"), 32 short, 32 long

Serial Number Blocks: Starting: 00001 Ending: 356,000

Variations: Improved Model 4,

No.4S Boy Scout Rifle

No.4S Military Rifle

I picked up the rifle and cleaned the dust. The surface of the barrel was covered with a thin layer of rust. It had been badly blued, probably many times over, ever since it landed in India which was probably in the 1920s. The stock had cracked around the grip and come apart. It was held together by a set of steel pins and glue. Some moron probably used it as a club, I said to myself.

Surprisingly, the action worked fine and all the screws and pins appeared original. The Remington insignia on the butt plate was still clear beneath the layer of rust. So was the serial number, except one figure, punched on the left of the receiver. I took the rifle apart and looked down the barrel. More than 30 per cent of the rifling was gone but my instincts told me it could still shoot tight groups up to a range of 50s mts and that's all I would ever want it to do.

"How much?" I asked the shop owner.

"Are you mad? You want to buy that rusted old junk?", said the man in disbelief.

But having known me for years he did not take more than a minute to know that I was serious.

"Ok Give me 8K," he said hesitatingly. He was not keen to make a profit out of what he thought was junk.

"How about 7?" I asked. Bargain, after all, is the middle name of every Bengali

"Done." the man shook his head.

I stepped out and lit up a cigarette. Lots of paperwork and arguments with the police was waiting for me....

A few months later I was back at the shop to take the rifle where it belonged.... the home of a five-year old kid

The actual restoration started a few weeks later. What worried me from the beginning was the stock. I had to make a new one, and a new forepart too since grains of the old one would not match the grains of whatever wood I chose for the stock.

Stock making was an unknown world to me, until now. The most I had done was a one piece grip for a Harrington and Richardson Sportsman my father once possessed. And that had taken me through myriad of trials and errors for months. At 47, I surely didn't have that patience, I thought, and started looking for Walnut.

A couple of big dealers in high quality timber said American Walnut could be procured but not in such small quantity and certainly not so fast.

Why not try Asian walnut, one of them suggested. So I got a 4' x 1' x 3" plank and started off. I have some basic carpentry tools at home and got a new more.

Asked a local table maker to show me how to draw basic layouts on raw timber. Thanks to my unruly schedules at office, the political turmoils in Bengal and my eternal laziness, it took me six months to make the stock. I was not being able to chisel out the channel in the forepart so I took help from the table maker.

Tools I used

I Wanted to oil finish the stock so imported Birchwood Casey oil finish from a dealer in UK. It took weeks and weeks of sanding, rubbing, polishing and oiling over and over again to get the desired results for the stock and forepart. But the final finish came from waxing. The oil is too shiny and so after eight coats and sanding I did a light oil finish and waxed the wood.

After first oil finish and sanding

The second last oil quote before I sanded it lightly to take off the extra shine

Towards final finish of the wood... You can compare the differences in these pics

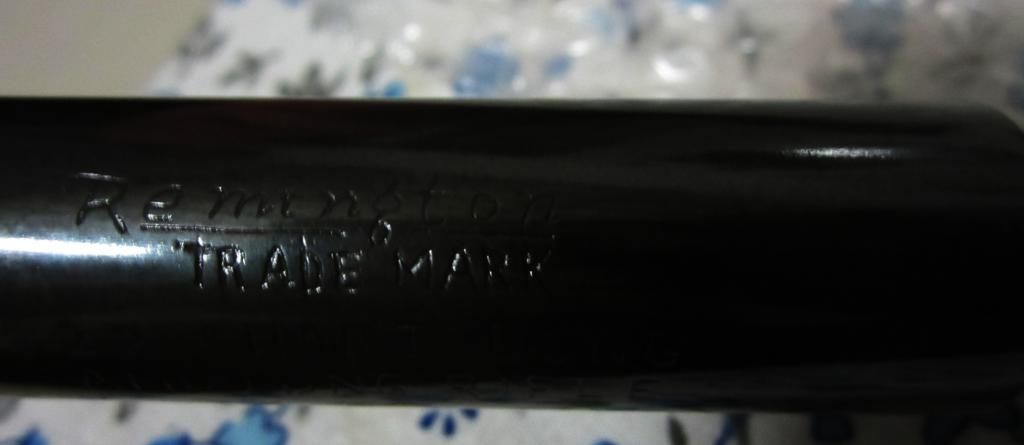

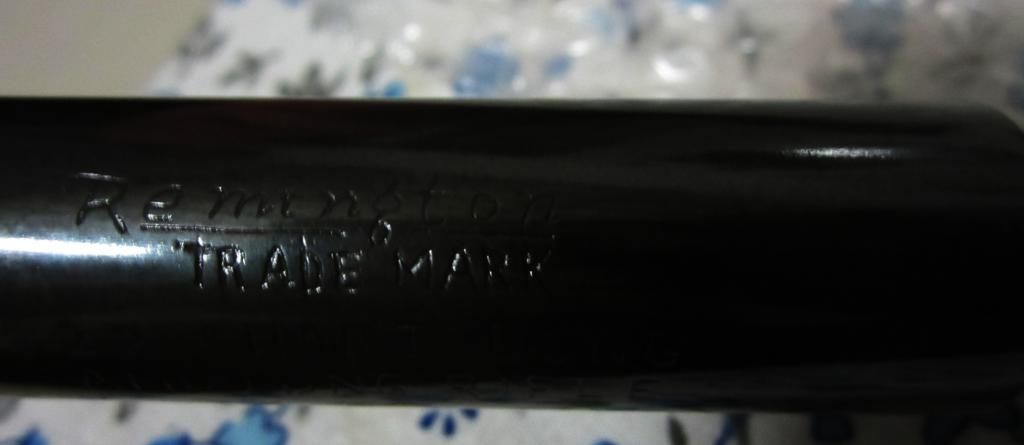

The markings on the barrel and receiver had to be touched up. This was another grey area and I did a bit on my own with a Dremel engraving machine (took it on loan from a cousin who makes miniature railroads and locos) and got a gunsmith to touch up some of the letters. I did a mess with a few letters but I am still happy.

My Spartan setup for the job. The Dremel engraving tool is certainly not meant for guns, at least not in the hands of a first timer

Taking off the rust and the old bluing, polishing all the metal parts and cold bluing them would be cakewalk, I had told myself on day one, since I have done it all so many times. I was wrong.

The bluing wasn't easy at all. Some parts, the muzzle crown for example, gave me BIG trouble. The metal is old and have gone through numerous acid dips and chemical baths in all these years. The Birchwood Casey liquid blue failed to bring the desired effect even after four coats. So I removed it entirely and started afresh with Klever Liquid Blue. And, I used Klever bluing granules for small parts such as the foresight and screws. The Germans saved the day

Polished the barrel, and all other metal parts, till they were as bright as my vic. Used paper of different grits. My fingers would go numb on some days.

The big bottle contains spirit that I get from a chemist to degrease metals

Foresight, takedown screw etc were treated with Klever bluing granules.

The finish after coats of B Casey blue was good but not good enough. So I started all over again

Klever did a better job. I am not sure though if you can make out from the photos

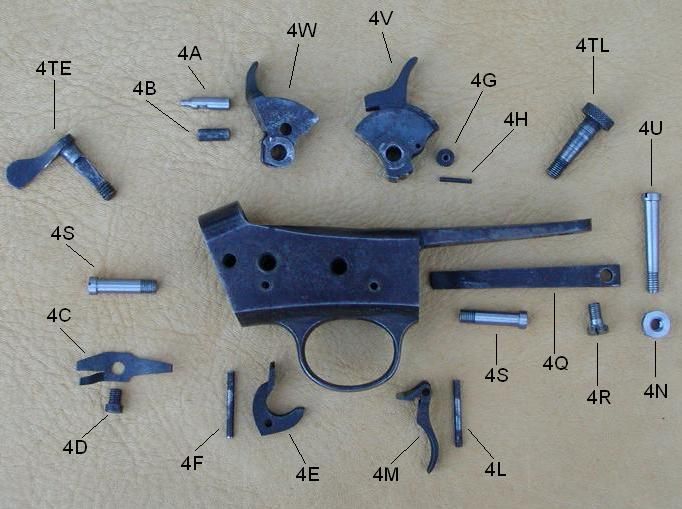

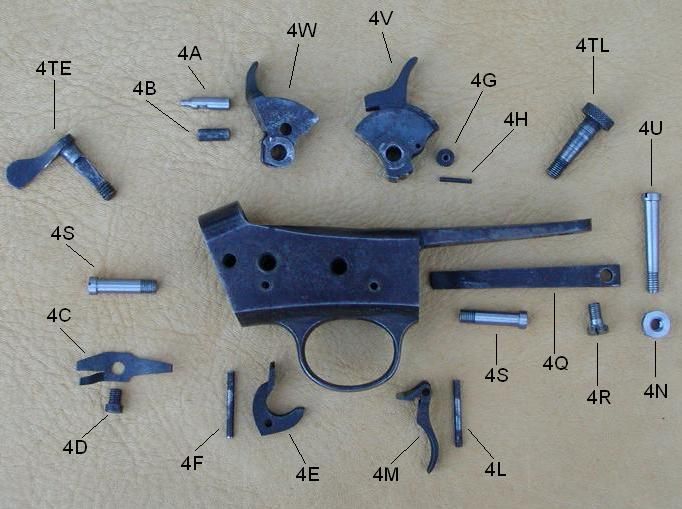

Some components inside this lovely yet simple design needed attention. The firing pin (No 4A in pic) had to be replaced since too much of dry firing had bamaged the face of the pin. I could get one from abroad but decided to make one myself from steel rod. Also, the front face of the half moon extractor (No 4E) that actually rocks on one of the arms of the three arm leaf spring (No 4C) needed some mending. Its front face had become thinner over the years so I took it to a local gate maker and got some extra steel welded to it which I later filed off according to need. Now it throws out empties like a dream.... KLIK KLAK .... KLIK KLAK

And now, the rifle. My Dad would have loved to see a classic that decided the fate of many battles in the 19th Century, not just on US soil but in Europe and even Africa. I dedicate this project to him.

And here is the great history of Remington from the NRA website

Eliphalet Remington II was born in Suffield, Connecticut on October 28, 1793. His father, Eliphalet Remington, moved his family from Connecticut to the Mohawk River Valley in 1800, where he cleared enough land for a small farm, built a two-room cabin that was later replaced by a larger home, and, along with others who had also moved to the region from Connecticut, established the town of Litchfield. Eliphalet Remington Sr. also owned an iron forge. Here he both fabricated and repaired tools, equipment, and hardware, and Lite, as Eliphalet II was nicknamed, worked alongside him and learned the trade as well.

The younger Remington had the opportunity to examine various long arms that were owned by local residents, and in 1816, he decided that he was capable of manufacturing a good rifle barrel. This he proceeded to do, and he took the finished product to a local gunsmith for boring and rifling. Lite then fitted a lock, stock, and furniture, and upon completion, he found that it shot well. After showing his new gun to area residents, he soon had a large number of orders for gun barrels. These were octagonal in shape, and as with his initial effort, boring and rifling was done by a gunsmith in nearby Utica. The completion of the Erie Canal in 1825 and the establishment of railroads soon thereafter provided an economic boost to the region. Remington's rifle barrel works expanded as well.

By 1828, he had established his own forge in Ilion, and he soon came to dominate the local trade, producing over 8,000 barrels per year for gunsmiths who would do final rifling and fitting. In 1844, Remington's oldest son, Philo, joined him in his business. This was reflected in the firm's name, which became E. Remington and Son.

By the mid-1850s, his two other sons, Samuel and Eliphalet III, had also joined the company, and the name changed yet again. In addition to gun barrels, E. Remington and Sons also manufactured plows, mowing machines, cotton gins, and firefighting equipment. In later years, their product line expanded to include bicycles, sewing machines, and typewriters. Remington's involvement in the manufacture of completed firearms came in 1848, when the company received a contract for the completion of 1,000 Jenks breechloading carbines for the U.S. Navy. In addition, Remington took over a defaulted contract from another manufacturer for the production of 5,000 U.S. Model 1841 "Mississippi" rifles. The business expanded through the 1850s, and handgun production began in 1857 with the introduction of the Remington-Beals pocket revolver.

The coming of the Civil War naturally brought about a dramatic increase in the demand for firearms, and Remington's production also increased to keep pace. During this period, the company manufactured both .36 and .44 caliber revolvers, as well as Model 1863 Percussion Contract Rifle, popularly known as the "Zouave" rifle. The post-war years brought smaller pocket pistols and deringers, the Remington-Smoot metallic cartridge pistols, Remington Single Action Army revolvers, rolling block rifles and pistols, slide, autoloading, and hammerless shotguns, and the Remington-Hepburn falling block rifles. During the 20th century, Remington has established itself as a manufacturer of high quality sporting arms, especially with upland game and bird hunters. The company also did its part during two World Wars as a manufacturer of military arms and munitions.

In addition to the M1911 semi-automatic pistol, the Browning Model 1917 heavy machine gun, and the Model 1917 bolt-action rifle, Remington also manufactured the Pedersen device. This was an early attempt to increase the firepower of individual infantry troops armed with the Springfield Model 1903 rifle. These rifles were modified by cutting the receiver wall to accommodate an ejection port, and the replacement of the bolt with a semi-automatic assembly that accepted a 40-round stick magazine loaded with the .30 caliber Pedersen, a pistol-class cartridge. Over 65,000 Pedersen devices were manufactured, but most were scrapped after the war. During the Second World War, Remington manufactured the M1903 (Modified) rifle, a transitional long arm in which stamped parts replaced some that had been milled in the earlier model, while other parts were dispensed with altogether in the interests of reducing production time. The company also manufactured the redesigned M1903A3 battle rifle and M1903A4 sniper rifle.

Eliphalet Remington II died in 1861, at which time Philo took over management of the company. Samuel died in 1882, and Philo purchased his share in the company. By 1886, E. Remington & Sons had experienced serious downturns, and the company went into receivership. In 1888, Marcellus Hartley, a partner in the New York sporting and military goods firm of Schuyler, Hartley, and Graham, as well as the founder and owner of the Union Metallic Cartridge Company, went together with Winchester Repeating Arms Company to purchase Remington. Each partner had an equal share of the firm, which was renamed Remington Arms Co., with Hartley serving as president and Thomas Bennett of Winchester assuming the role of vice president.

In 1896, Winchester sold its stake in Remington to Hartley. Marcellus Hartley died in 1902, and leadership of the company passed to Marcellus Hartley Dodge. In 1910, Remington Arms and Union Metallic Cartridge were merged into a single company, known as Remington-UMC. In 1934, both company's name and ownership changed as Remington-U.M.C. was purchased by DuPont and reorganized as the Remington Arms Co., Inc. The Ilion armsmaker remained a part of the DuPont organization until 1993, when Remington was purchased by the investment group of Clayton Dubilier Rice.

By best wishes to all my friends. Hope you will like this thread.

Incidentally, this is my longest post in eight years

TC

I was a kid when my dad took me to a movie on that day. Halfway through the movie (I can't recollect the name anymore) a rifle grabbed my attention. A man was loading one bullet at a time and pulling a lever like object that made the empties fly out. It had a long shiny barrel and lovely wooden stock..... I was awestruck.

"That's a Remington rolling block rifle," my father later told me. Soon, this rifle turned into an obsession that I never talked about. But I never again saw a Remington Rolling Block in real life.

Last year, I was visiting an old gun shop in Kolkata when something kept against the wall in a dusty corner caught my eyes and all my attention.

A Remington Rolling Block No 4 later model or the Improved Model 4 with round barrel and distinctively large take down screw. Fires .22 short, long and long rifle. Comes apart in a few seconds and neatly packs into a 24 inch bag. I could hear my heart beat.

OVERVIEW: from here http://www.remington.com/products/archi ... block.aspx

Description: Rolling Block Rifle

Introduction Year: 1890

Year Discontinued: 1933

Total Production: Approximately 356,000

Designer/Inventor: F.A. Houghton, J.O. Simpson, O.H. Loomis

Action Type: Single Shot

Caliber/Gauge: 22 short, 22 long, 22 long rifle, 25 Stevens ("25-10"), 32 short, 32 long

Serial Number Blocks: Starting: 00001 Ending: 356,000

Variations: Improved Model 4,

No.4S Boy Scout Rifle

No.4S Military Rifle

I picked up the rifle and cleaned the dust. The surface of the barrel was covered with a thin layer of rust. It had been badly blued, probably many times over, ever since it landed in India which was probably in the 1920s. The stock had cracked around the grip and come apart. It was held together by a set of steel pins and glue. Some moron probably used it as a club, I said to myself.

Surprisingly, the action worked fine and all the screws and pins appeared original. The Remington insignia on the butt plate was still clear beneath the layer of rust. So was the serial number, except one figure, punched on the left of the receiver. I took the rifle apart and looked down the barrel. More than 30 per cent of the rifling was gone but my instincts told me it could still shoot tight groups up to a range of 50s mts and that's all I would ever want it to do.

"How much?" I asked the shop owner.

"Are you mad? You want to buy that rusted old junk?", said the man in disbelief.

But having known me for years he did not take more than a minute to know that I was serious.

"Ok Give me 8K," he said hesitatingly. He was not keen to make a profit out of what he thought was junk.

"How about 7?" I asked. Bargain, after all, is the middle name of every Bengali

"Done." the man shook his head.

I stepped out and lit up a cigarette. Lots of paperwork and arguments with the police was waiting for me....

A few months later I was back at the shop to take the rifle where it belonged.... the home of a five-year old kid

The actual restoration started a few weeks later. What worried me from the beginning was the stock. I had to make a new one, and a new forepart too since grains of the old one would not match the grains of whatever wood I chose for the stock.

Stock making was an unknown world to me, until now. The most I had done was a one piece grip for a Harrington and Richardson Sportsman my father once possessed. And that had taken me through myriad of trials and errors for months. At 47, I surely didn't have that patience, I thought, and started looking for Walnut.

A couple of big dealers in high quality timber said American Walnut could be procured but not in such small quantity and certainly not so fast.

Why not try Asian walnut, one of them suggested. So I got a 4' x 1' x 3" plank and started off. I have some basic carpentry tools at home and got a new more.

Asked a local table maker to show me how to draw basic layouts on raw timber. Thanks to my unruly schedules at office, the political turmoils in Bengal and my eternal laziness, it took me six months to make the stock. I was not being able to chisel out the channel in the forepart so I took help from the table maker.

Tools I used

I Wanted to oil finish the stock so imported Birchwood Casey oil finish from a dealer in UK. It took weeks and weeks of sanding, rubbing, polishing and oiling over and over again to get the desired results for the stock and forepart. But the final finish came from waxing. The oil is too shiny and so after eight coats and sanding I did a light oil finish and waxed the wood.

After first oil finish and sanding

The second last oil quote before I sanded it lightly to take off the extra shine

Towards final finish of the wood... You can compare the differences in these pics

The markings on the barrel and receiver had to be touched up. This was another grey area and I did a bit on my own with a Dremel engraving machine (took it on loan from a cousin who makes miniature railroads and locos) and got a gunsmith to touch up some of the letters. I did a mess with a few letters but I am still happy.

My Spartan setup for the job. The Dremel engraving tool is certainly not meant for guns, at least not in the hands of a first timer

Taking off the rust and the old bluing, polishing all the metal parts and cold bluing them would be cakewalk, I had told myself on day one, since I have done it all so many times. I was wrong.

The bluing wasn't easy at all. Some parts, the muzzle crown for example, gave me BIG trouble. The metal is old and have gone through numerous acid dips and chemical baths in all these years. The Birchwood Casey liquid blue failed to bring the desired effect even after four coats. So I removed it entirely and started afresh with Klever Liquid Blue. And, I used Klever bluing granules for small parts such as the foresight and screws. The Germans saved the day

Polished the barrel, and all other metal parts, till they were as bright as my vic. Used paper of different grits. My fingers would go numb on some days.

The big bottle contains spirit that I get from a chemist to degrease metals

Foresight, takedown screw etc were treated with Klever bluing granules.

The finish after coats of B Casey blue was good but not good enough. So I started all over again

Klever did a better job. I am not sure though if you can make out from the photos

Some components inside this lovely yet simple design needed attention. The firing pin (No 4A in pic) had to be replaced since too much of dry firing had bamaged the face of the pin. I could get one from abroad but decided to make one myself from steel rod. Also, the front face of the half moon extractor (No 4E) that actually rocks on one of the arms of the three arm leaf spring (No 4C) needed some mending. Its front face had become thinner over the years so I took it to a local gate maker and got some extra steel welded to it which I later filed off according to need. Now it throws out empties like a dream.... KLIK KLAK .... KLIK KLAK

And now, the rifle. My Dad would have loved to see a classic that decided the fate of many battles in the 19th Century, not just on US soil but in Europe and even Africa. I dedicate this project to him.

And here is the great history of Remington from the NRA website

Eliphalet Remington II was born in Suffield, Connecticut on October 28, 1793. His father, Eliphalet Remington, moved his family from Connecticut to the Mohawk River Valley in 1800, where he cleared enough land for a small farm, built a two-room cabin that was later replaced by a larger home, and, along with others who had also moved to the region from Connecticut, established the town of Litchfield. Eliphalet Remington Sr. also owned an iron forge. Here he both fabricated and repaired tools, equipment, and hardware, and Lite, as Eliphalet II was nicknamed, worked alongside him and learned the trade as well.

The younger Remington had the opportunity to examine various long arms that were owned by local residents, and in 1816, he decided that he was capable of manufacturing a good rifle barrel. This he proceeded to do, and he took the finished product to a local gunsmith for boring and rifling. Lite then fitted a lock, stock, and furniture, and upon completion, he found that it shot well. After showing his new gun to area residents, he soon had a large number of orders for gun barrels. These were octagonal in shape, and as with his initial effort, boring and rifling was done by a gunsmith in nearby Utica. The completion of the Erie Canal in 1825 and the establishment of railroads soon thereafter provided an economic boost to the region. Remington's rifle barrel works expanded as well.

By 1828, he had established his own forge in Ilion, and he soon came to dominate the local trade, producing over 8,000 barrels per year for gunsmiths who would do final rifling and fitting. In 1844, Remington's oldest son, Philo, joined him in his business. This was reflected in the firm's name, which became E. Remington and Son.

By the mid-1850s, his two other sons, Samuel and Eliphalet III, had also joined the company, and the name changed yet again. In addition to gun barrels, E. Remington and Sons also manufactured plows, mowing machines, cotton gins, and firefighting equipment. In later years, their product line expanded to include bicycles, sewing machines, and typewriters. Remington's involvement in the manufacture of completed firearms came in 1848, when the company received a contract for the completion of 1,000 Jenks breechloading carbines for the U.S. Navy. In addition, Remington took over a defaulted contract from another manufacturer for the production of 5,000 U.S. Model 1841 "Mississippi" rifles. The business expanded through the 1850s, and handgun production began in 1857 with the introduction of the Remington-Beals pocket revolver.

The coming of the Civil War naturally brought about a dramatic increase in the demand for firearms, and Remington's production also increased to keep pace. During this period, the company manufactured both .36 and .44 caliber revolvers, as well as Model 1863 Percussion Contract Rifle, popularly known as the "Zouave" rifle. The post-war years brought smaller pocket pistols and deringers, the Remington-Smoot metallic cartridge pistols, Remington Single Action Army revolvers, rolling block rifles and pistols, slide, autoloading, and hammerless shotguns, and the Remington-Hepburn falling block rifles. During the 20th century, Remington has established itself as a manufacturer of high quality sporting arms, especially with upland game and bird hunters. The company also did its part during two World Wars as a manufacturer of military arms and munitions.

In addition to the M1911 semi-automatic pistol, the Browning Model 1917 heavy machine gun, and the Model 1917 bolt-action rifle, Remington also manufactured the Pedersen device. This was an early attempt to increase the firepower of individual infantry troops armed with the Springfield Model 1903 rifle. These rifles were modified by cutting the receiver wall to accommodate an ejection port, and the replacement of the bolt with a semi-automatic assembly that accepted a 40-round stick magazine loaded with the .30 caliber Pedersen, a pistol-class cartridge. Over 65,000 Pedersen devices were manufactured, but most were scrapped after the war. During the Second World War, Remington manufactured the M1903 (Modified) rifle, a transitional long arm in which stamped parts replaced some that had been milled in the earlier model, while other parts were dispensed with altogether in the interests of reducing production time. The company also manufactured the redesigned M1903A3 battle rifle and M1903A4 sniper rifle.

Eliphalet Remington II died in 1861, at which time Philo took over management of the company. Samuel died in 1882, and Philo purchased his share in the company. By 1886, E. Remington & Sons had experienced serious downturns, and the company went into receivership. In 1888, Marcellus Hartley, a partner in the New York sporting and military goods firm of Schuyler, Hartley, and Graham, as well as the founder and owner of the Union Metallic Cartridge Company, went together with Winchester Repeating Arms Company to purchase Remington. Each partner had an equal share of the firm, which was renamed Remington Arms Co., with Hartley serving as president and Thomas Bennett of Winchester assuming the role of vice president.

In 1896, Winchester sold its stake in Remington to Hartley. Marcellus Hartley died in 1902, and leadership of the company passed to Marcellus Hartley Dodge. In 1910, Remington Arms and Union Metallic Cartridge were merged into a single company, known as Remington-UMC. In 1934, both company's name and ownership changed as Remington-U.M.C. was purchased by DuPont and reorganized as the Remington Arms Co., Inc. The Ilion armsmaker remained a part of the DuPont organization until 1993, when Remington was purchased by the investment group of Clayton Dubilier Rice.

By best wishes to all my friends. Hope you will like this thread.

Incidentally, this is my longest post in eight years

TC