Page 1 of 2

revolver speedloaders

Posted: Sun Aug 05, 2007 10:53 am

by james

My best friend is having smith&wesson .32 model36 snub nose revolver,we tried our level best but could not get speedloader for his revolver in eastern India.Please guide us where we get this in india and at what price.Regards James..

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 11:18 am

by penpusher

James,

If you want I can check out with a dealer in Chandigarh who used to advertise for them and if the price is ok with you can post you one.Will be not before next week though.

penpusher

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 11:43 am

by Mark

James,

I've not seen a model 36 in 32 caliber, is it 5 or 6 shot?

At any rate, If you find these impossible to locate in your state and do not have a friend who can purchase one in the USA and bring it back in luggage, they are easy to make with hand tools and look nice too.

If you are interested in this let me know and I'll type out how to do it, otherwise it's a bit of typing for a hunt and peck kinda guy!

Mark

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 1:15 pm

by Lever Action

James ,

Visit

www.gsmithco.com in the accessory section and you will find speed loaders for smith & wesson revolvers and for details you can call them.

Lever Action

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 1:29 pm

by mashh1

Hi Mark

i will love to see the do it yourself speedloader. i want them for my colt police positive in 38 special. i have seen HKS loaders for newer colts but they did not work with my gun as they have a wider rim. i once try to get them fabricated but it did not worked out. it will be very helpful for all who needs them and cant get them.

regards

mashh

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 5:19 pm

by cottage cheese

Mark";p="24485 wrote:James,

I've not seen a model 36 in 32 caliber, is it 5 or 6 shot?

At any rate, If you find these impossible to locate in your state and do not have a friend who can purchase one in the USA and bring it back in luggage, they are easy to make with hand tools and look nice too.

If you are interested in this let me know and I'll type out how to do it, otherwise it's a bit of typing for a hunt and peck kinda guy!

Mark

Hey Mark,

Though its apparently available in country through gsmithco.com , I'd rather try the hands on approach... I like self sufficiency. Would love to take a look at the build info you have.

Thanks!

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 5:25 pm

by penpusher

Mark,

Look forward to the lesson on the DIY speed loader.In our part of the woods sometimes that's the only way to go.

penpusher

Re: revolver speedloaders

Posted: Sun Aug 05, 2007 9:56 pm

by Mark

Since there are a few people interested in this, let me do a good job of it and make up some drawings. I'll try to get them done and posted tonight.

Mark

Re: revolver speedloaders

Posted: Mon Aug 06, 2007 12:15 pm

by Mark

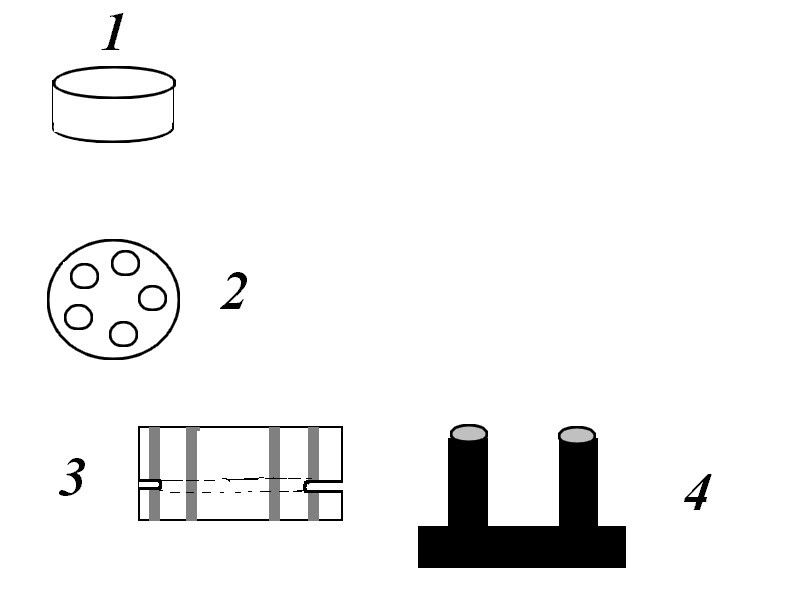

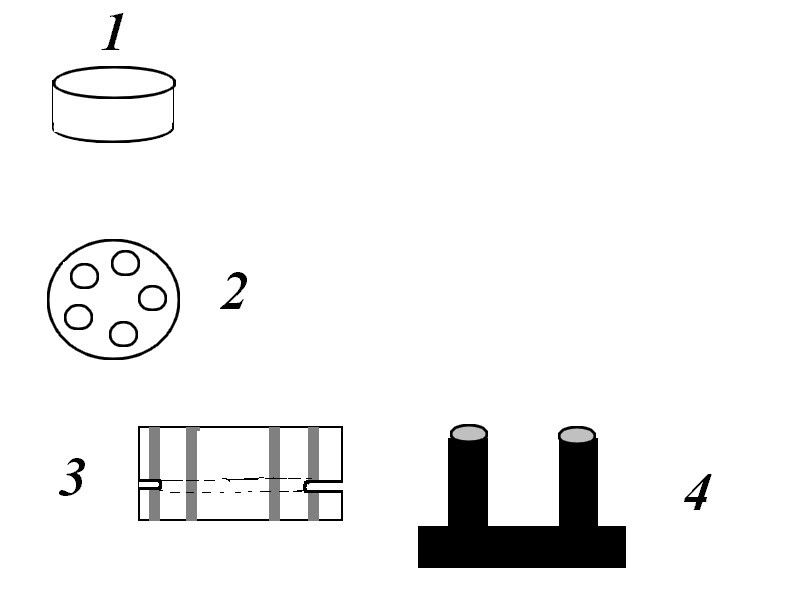

OK all, please forgive my crude drawing here!

Here is the pic and the explanation will follow:

Step 1- Fabricate a round block the same diameter as your cylinder. This can be of most any material- wood, plastic, fiberglass, heck even aluminum would work. For the length, measure the length of the brass (just the brass, not the bullet) and add 3/8" (10mm).

Step 2- Mark and drill the holes. The holes need to be the diameter of the rim , not the body of the cartridge.

Step 3- Cut a groove all around the outside of the body. This is best done with a table saw or just by hand with a wood rasp or whatever. Cut deep enough that is cuts in to the chamber about 1/8". When I made these growing up, I just used a rubber band in this groove to hold the cartridges, but they break after 2 or 3 loadings. That is not really a problem as they always would hold the cartridges but would get cut by the rim during loading but it really doesn't matter because at that point the bulets are going in to the chamber anyway. Nowadays how I'd do it would be go to a tool supply house or auto parts store and get some large O-Rings instead, I bet they'd last forever.

Step 4- This is the "pusher", it is a base with wooden dowels that are cut to the length of the chamber. When the block is pushed fully into the part #1, expect the pegs to be almost flush. Chamfer off the sharp edge slightly, especially on the outside where it will be pushing up the O-Ring when it goes past.

That is all there is to it, except for the retainer which is just a wood screw. First drill through the center of the cylinder part with a 1/8" drill bit, then follow with a 5/16" almost all the way except for that 3/8" space at the bottom. Now get a long wood screw to hold both parts together, you want the wooden plugs to be 3/8" into the chambers and held well enough it does not fall out.

To use, just push the cartridges in each chamber where the friction from the band or O-Ring keeps it in place. When you need to load your gun just line up the bullets and give the back of the block a push and they will just slide right in to the guns cylinder!

A couple of notes- When I first designed these back in the stone age, I had a sheet of very stiff foam rubber. Before I hit on making a groove and using rubber bands I had taken a sheet of the foam and glued that over the end instead and had drilled much smaller holes in that, which held the bullets OK. The problem was after a while the glue came off and everything would fall apart once that happened. However, that is another way to do it and maybe someone has better glue than what I used.

Another thing that I did was stretch a section of bicycle inner tube over the outside, it made it look a lot nicer. The only issue you have to watch out for is make sure you cut the groove for the ring in the middle or towards the back of the chamber. I had on where I had the cut right up at the other end and occasionally a fold of the inner tube would get caught up and it wouldn't push the cartridges in all the way past the rubber band and they'd hang up.

Have fun! This sounds kinda funny as I write this, but back when I was growing up speedloaders were only used by policemen and were quite expensive, especially for a teenager.

Re: revolver speedloaders

Posted: Mon Aug 06, 2007 2:41 pm

by mashh1

thanks a lot mark

i can imagine where my next weekend is heading

Posted: Mon Aug 06, 2007 6:13 pm

by mundaire

Thank you Mark - a simple and eminently "doable" project!

Posted: Mon Aug 06, 2007 7:19 pm

by HSharief

Mark, I'm impressed by your craftsmanship.

How would one do moon clips, full or half. I know a lot of people use the speed loaders like you described, but I like the look and feel of the moon clips, full, if I can hold them on the belt and halves if I have to put them in the pocket. I'm sure stamped metal or some kind of tough plastic could be cut the right way to make these.

http://www.ezmoonclip.com/

Re: revolver speedloaders

Posted: Mon Aug 06, 2007 7:47 pm

by cottage cheese

Mark,

Big thanks for the share. Now things in the shop are going to get upset!...

Posted: Mon Aug 06, 2007 10:04 pm

by shutzen

How would one do moon clips, full or half. I know a lot of people use the speed loaders like you described, but I like the look and feel of the moon clips, full, if I can hold them on the belt and halves if I have to put them in the pocket. I'm sure stamped metal or some kind of tough plastic could be cut the right way to make these.

http://www.ezmoonclip.com/

HI! Hsharief I agree with your thought about the moon clips the . U can forget about using stamping spring steel for a experimental project since it entails getting a expensive die made. Spark erosion /edp are also out as they could affect the temper of the steel. However from my experience the ideal solution would be to use a waterjet

since its a cold process there is no effect on the properties of the spring steel sheet . The dude I got some work done from charges Rs. 400/- per foot and I think in one foot u should have enough full and half moon clips to last u a lifetime! the computerised jet cuts with unbelievable accuracy and its pretty quick too. U just have to give him a corel draw or a autocad drawing of the job otherwise simply give him a drawing and he charges Rs. 150/- to convert it. Think about it and let me know the results

Posted: Mon Aug 06, 2007 10:34 pm

by Mark

HSharief";p="24541 wrote:Mark, I'm impressed by your craftsmanship.

How would one do moon clips, full or half. I know a lot of people use the speed loaders like you described, but I like the look and feel of the moon clips, full, if I can hold them on the belt and halves if I have to put them in the pocket. I'm sure stamped metal or some kind of tough plastic could be cut the right way to make these.

http://www.ezmoonclip.com/

I've never fooled around with half moon clips to be honest.

I would try to trace one out on something like circuit board material, and then use a dot of super glue to hold the cartridges in place, but as I said this is all just a guess.