Page 1 of 2

Shotgun Restocking Project (Pics)

Posted: Wed Jan 13, 2016 7:42 pm

by herb

I have to restock a custom shotgun and just started on the project, planning to update pictures of the progress for the benefit of members here who may be considering restocking in the near future.

Pics of the stock blank. It is important to consider the grain flow thru the wrist area. Structural integrity of the stock is no 1. Beauty comes second on a gun that will be shot a lot.

Herb

Re: Shotgun Restocking Project (Pics)

Posted: Sun Jan 17, 2016 12:43 am

by herb

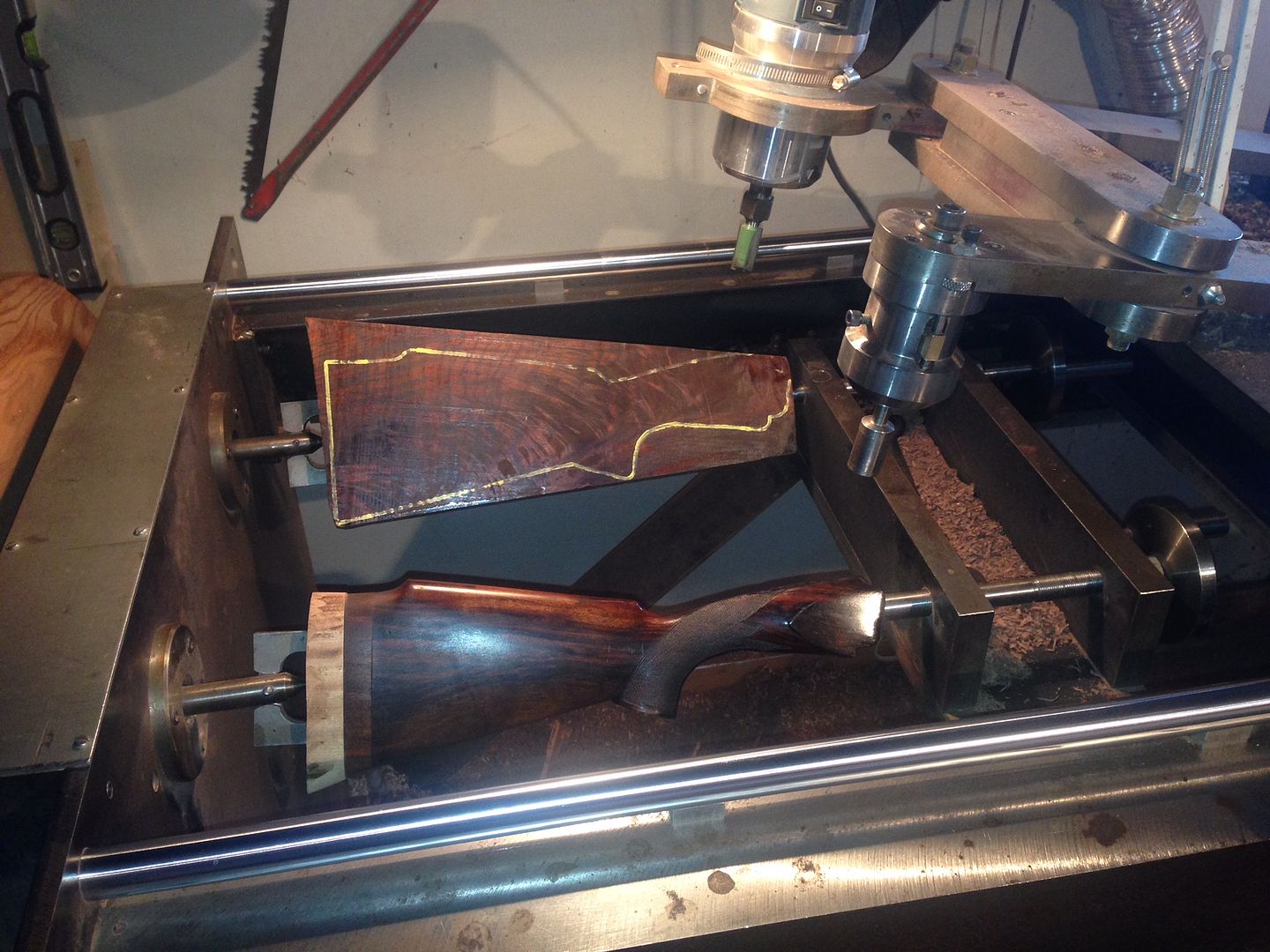

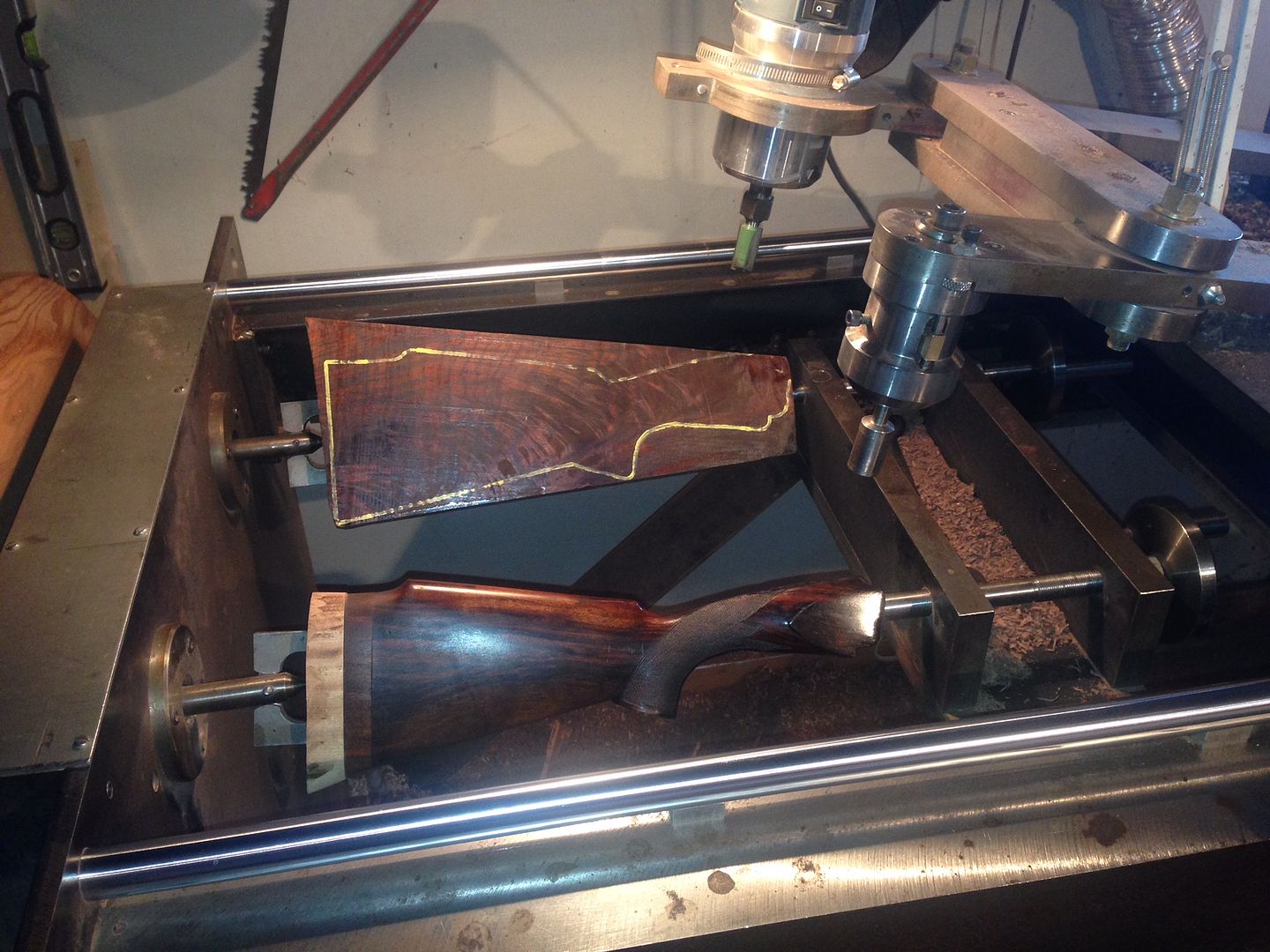

A pattern stock with the required measurements....

In the duplicator.....

Cheers!

Re: Shotgun Restocking Project (Pics)

Posted: Sun Jan 24, 2016 4:32 am

by herb

Duplication in progress....

Re: Shotgun Restocking Project (Pics)

Posted: Fri Jan 29, 2016 3:34 am

by herb

Progressing slowly....

Re: Shotgun Restocking Project (Pics)

Posted: Fri Jan 29, 2016 12:23 pm

by Trajeev

Very Nice

.Is it a 3D pentograph machine? What is the tool RPM? If you are using HF spindle,a ball head will give better finish.

Re: Shotgun Restocking Project (Pics)

Posted: Fri Jan 29, 2016 12:26 pm

by ckkalyan

Wow, very cool process

herb - I can only imagine the thrill, watching the blank taking shape almost, magically!

Re: Shotgun Restocking Project (Pics)

Posted: Fri Jan 29, 2016 2:54 pm

by Vikram

Herb,

Lovely piece of wood there. Is it a Trap gun?

Best-

Vikram

Re: Shotgun Restocking Project (Pics)

Posted: Sat Jan 30, 2016 4:39 am

by herb

Trajeev wrote:Very Nice

.Is it a 3D pentograph machine? What is the tool RPM? If you are using HF spindle,a ball head will give better finish.

Yes it is a pentograph, the stock will be hand finished after in-letting.

ckkalyan wrote:Wow, very cool process

herb - I can only imagine the thrill, watching the blank taking shape almost, magically!

Yes it is an very interesting project.

Vikram wrote:Herb,

Lovely piece of wood there. Is it a Trap gun?

Best-

Vikram

I am also looking forward to how the stock will come out and yes, it is a trap / skeet combo.

Re: Shotgun Restocking Project (Pics)

Posted: Sun Jan 31, 2016 6:00 am

by herb

Getting the inlet around the head, my gunsmith will have to spend a couple of hours for a proper fit. Much easier on a boxlock compared to a sidelock.

Re: Shotgun Restocking Project (Pics)

Posted: Sat Feb 06, 2016 7:35 pm

by herb

Re: Shotgun Restocking Project (Pics)

Posted: Mon Feb 08, 2016 9:29 pm

by shooter

Herb why did you choose the Monte Carlo style ESP with cheek piece?

Re: Shotgun Restocking Project (Pics)

Posted: Mon Feb 08, 2016 11:42 pm

by abhrankash

I think this is the copy milling machine. The best way to get the 0-0 stock is to scan the required stock under white light scanner you will get the point cloud data from those point cloud data surface can be generated by using CAD software and then converted to solid. that data can be transferred to the machine either by LAN or WI-FI and can be machined by CNC milling or CNC routing (wood working). but this is a lengthy and costly process but the method you have shown is a cheap and easy process.

Re: Shotgun Restocking Project (Pics)

Posted: Mon Feb 08, 2016 11:45 pm

by abhrankash

copy milling is the only machine in which you can have the 1:1 ratio manufacturing but this machine is little slow if you can compare with the present day scenario of manufacturing.

Re: Shotgun Restocking Project (Pics)

Posted: Tue Feb 09, 2016 6:45 am

by herb

shooter wrote:Herb why did you choose the Monte Carlo style ESP with cheek piece?

Shooter - This is a 2 barrel set with trap / skeet combo. I prefer a Monte Carlo stock for trap. Just a personal preference, I did debate about the cheek piece.

abhrankash wrote:I think this is the copy milling machine. The best way to get the 0-0 stock is to scan the required stock under white light scanner you will get the point cloud data from those point cloud data surface can be generated by using CAD software and then converted to solid. that data can be transferred to the machine either by LAN or WI-FI and can be machined by CNC milling or CNC routing (wood working). but this is a lengthy and costly process but the method you have shown is a cheap and easy process.

"but this is a lengthy and costly process but the method you have shown is a cheap and easy process."

abhrankash - Please forgive my ignorance but I would like to know more about the

"0-0 stock" process you have mentioned. Never heard of the process you have mentioned for custom stock making, do you have any pictures of a finished stock using this process? How much does it cost to finish a stock using this process?

Went this route to save my gunsmith from starting from the blank by hand. It is now in the process of being hand finished and fitted to the action by

Nick Makinson using techniques that were used at the beginning of the last century. Nick is a British gun-maker who has made some fabulous guns including double rifles in calibers up to 600 Nitro Express. Please checkout his website for more information.

Inletting is done using a kerosene oil lamp to blacken the action, determine the contact on the wood where the black has been transfered to the wood, and then hand chiseled for a perfect fit, this has to be repeated many many times as only a minute amount of wood is removed each time. As you can see this is a very long and tedious process. Some pics of Nick working on my stock....

I am estimating at-least another 20-22 hours of work by hand including the oil finish (over a period of 3-4 months allowing for drying of the multiple coats of oil depending on the humidity) , at $100+ an hour just the finishing and fitting is going to set me back by $2500+. Not exactly cheap in my world and hence would like to explore other options for future projects including the one you have mentioned.

Re: Shotgun Restocking Project (Pics)

Posted: Tue Feb 09, 2016 1:27 pm

by shooter

Good one herb. Nice stick and still done the old way.

Fitting the stock is a very continental art. Good to see it done old style across the pond.

My friend is a gunsmith and has the duplicator machine however he can not measure and fit to individuals. That is a different skill set.

Good luck with everything. And keep us posted. Also drop me a pm about how one can get to meet you